Key advantages

Meets all national fire prevention building codes

Allows existing lighting, ventilation and fire suppression systems

Anti rust powder coated finish

Detailed drawings provided with each order

Custom made to fit your needs

Options

- Special colors

- 16g sheet metal

- Expanded sheet metal

- 2″x 2″ posts (50 mm x 50 mm x 16 g)

With this storage option, you’ll get

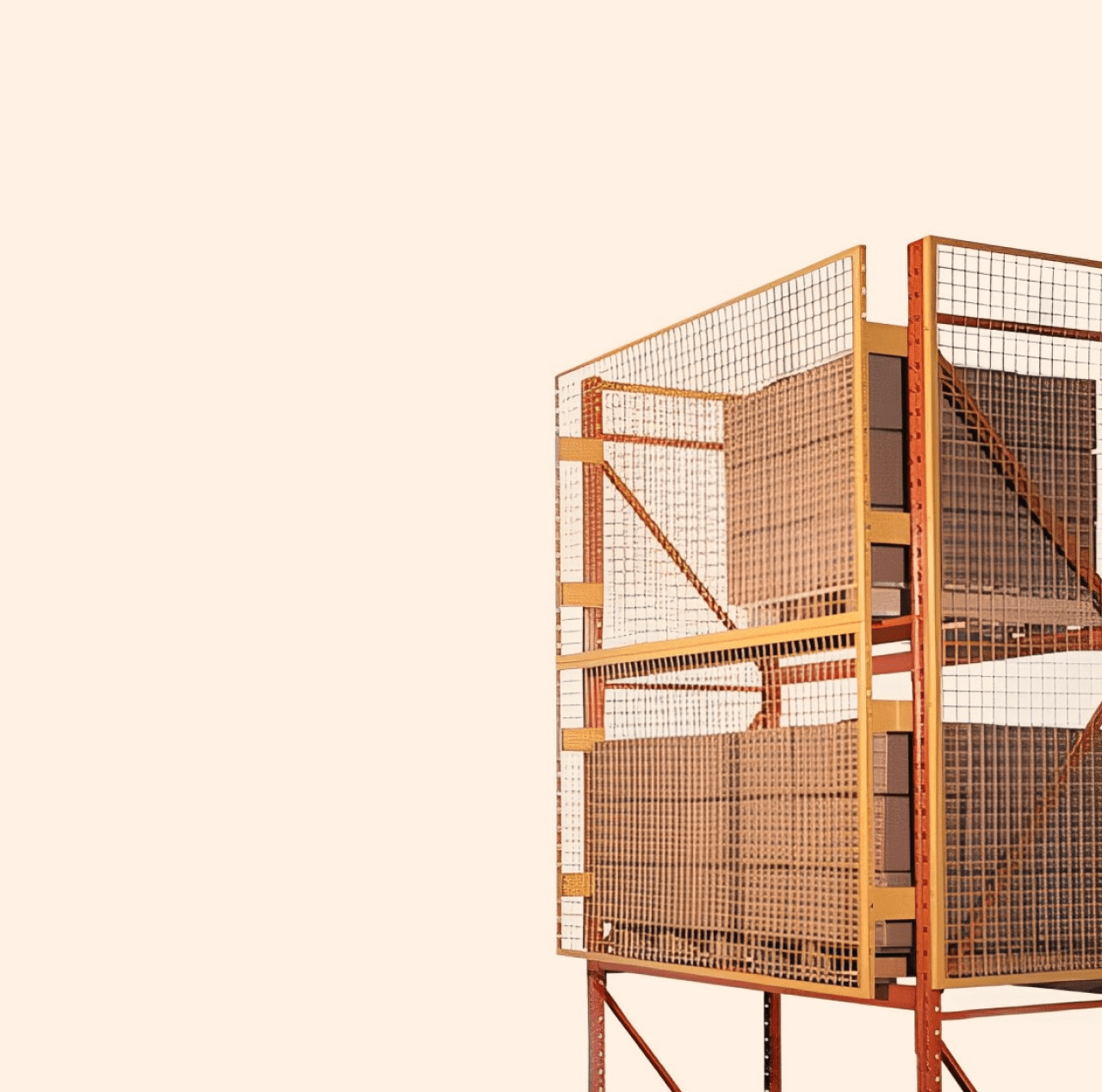

- Wire mesh welded at each intersection for stronger cut-outs and no fabric tears

- Options such as triple tier lockers or sheet metal, for different types of storage

- Pre-punched components make these lockers easy to install using ordinary hand tools

- Painted with baked grey powder coat over phosphate-treated steel for lasting durability and protection against corrosion

- Made from mesh that is solidly welded into an angle frame – not simply wire mesh with brackets

Materials

Panels

Shall be 10g wire spot welded into 2'' x 2'' squares (50mm x 50mm x 3.2mm wire) welded into an angle frame of 1 ¼'' x 1 ¼'' x 12 angle ( 32mm x 32mm x 3mm ) welded at every 8'' inches (200mm) . All panels shall be fastened to floor and walls using 1/4'' x 1 1/4'' (6.4mm x 32mm) drive nails. All panels shall be fastened using 1/4'' x 3/4'' (6.4mmx 19mm) zinc bolts and nuts

Swing doors

Swing doors shall be made of the same material and method as panels with an added ½'' rod ( 12.5mm) form center to corners . Doors shall be equipped with padlock lugs, door strikes and 1 1/2 pair of hinges

Finish

Baked grey powder over a phosphate treated steel

Ceilings

Shall be 2''x 4''x 1/8'' rectangles (50mm x 100mm) wire framed with 1 1/4''x 1 1/4'' x 12g angle (32mm x 32mm x 3mm ) angle on perimeters and secured with wire loop toes ( option framed tops available)

Shelves

Shall be constructed of 22g galvanized steel. Option of 2'' x 2'' squares (50mm x 50mm x 3.2mm ) wire